PFAS – what we know and what we do not know yet

Interview with the industry association Spectaris

PFAS are a group of industrial chemicals comprising a very large number of substances., the number is estimated at approximately 10,000. Due to their special properties, the substances have been widely used for a long time in many industrial sectors and also in the household. However, many PFAS are toxic, accumulate through the food chain or are mobile and once released into the environment they are difficult or impossible to remove. Therefore, a ban is under discussion that could also affect spectacle lenses. MAFO has talked to the industry association Spectaris about the current situation. By Hanna Diewald

Which products do contain PFAS (in the ophthalmic industry)?

To answer this question, some background is necessary: Denmark, Germany, the Netherlands, Norway and Sweden have submitted a proposal to restrict the use of polyfluoroalkyl substances (PFAS), with some use-specific, time-limited exemptions based on the availability and applicability of alternatives.

The proposed PFAS restrictions are the subject of study and extensive debate affecting numerous products, including medical devices, which include ophthalmic products.

All manufacturing companies are currently required to evaluate the extent to which their products contain one or more of the 10,000 substances. These tests are in full swing.

Since optical medical devices, which include frames, lenses and contact lenses, represent a wide range of materials, it is not possible to give a defini- tive answer to such a question at this time. To the best of our knowledge, ophthalmic lenses and contact lenses are most likely to be affected. The PFAS in high-performance materials will be the political undoing of precisely the technical property because of which they are used and are predominantly irreplaceable: their durability and resistance in industrial high-tech products, essential applications in medical technology and, of course, in ophthalmic optics products.

One thing is clear: if PFAS are present in products, it will most likely be difficult to replace them and still be able to manufacture medical products of the same high quality.

PFAS are said to be contained in coatings for spectacle lenses. Can you already say, at this stage, in which part of the coating exactly are PFAS usually used?

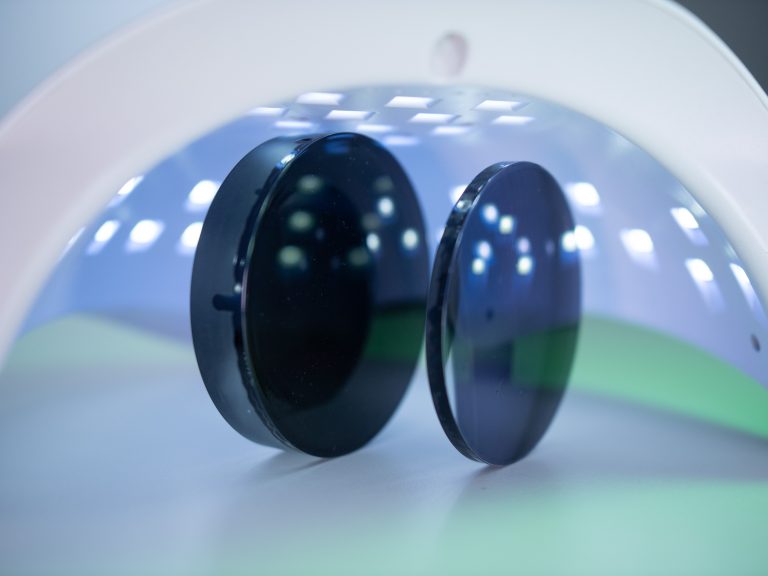

Modern premium spectacle lenses, such as those manufactured in Europe, are characterized by their optical performance, individual correction, as well as their long life and convenient use. Scratch resistant coatings, easy-to-clean-, and anti-reflective coatings contribute sig- nificantly to this. Modern premium lenses therefore contain PFAS in extremely small quantities.

These top coating layers provide dirt-repellent and easy cleaning properties. These coatings significantly increase the service life of spectacle lenses, which are subject to a great deal of wear and tear in everyday use due to dust, dirt and cleaning.

This is not only a matter of convenient cleaning and thus convenience for spectacle wearers, but also a matter of safety: clean and scratch- resistant lenses enable the best possible vision, especially in safety- relevant situations such as driving, in road traffic.

Are there coated lenses that do not contain PFAS at all?

In principle, yes, but they do not have the advantages mentioned. The service life of such lenses is dramatically shorter. The quality of vision and the associated main function of the lenses is also severely impaired.

The vast majority of all premium lenses sold in Europe are equipped with high-performance coatings – a clear added value for customers and patients and a competitive advantage over no-name or low-cost suppliers from Asia.

Can you currently estimate exactly what impact a ban on all PFAS could have on the ophthalmic lens industry?

Currently, there are no known alternatives with comparable properties. With considerable effort and lead time, these could possibly be developed. In the short and medium term, however, a PFAS ban would reduce an important competitive advantage of European quality manufacturers and consumers would probably switch to cheap products from non-European production.

A shorter service life – due to higher stress on the lens surfaces from dust, dirt, cosmetic and other substances that are less easily removed – leads to the need to replace spectacle lenses more frequently, with the associated increased consumption of resources.

What can and should affected manufacturers do now?

Manufacturers support the move away from substances that are hazardous to the environment and people, and are making corresponding avoidance and substitution efforts to this end as part of their sustainability strategies.

Specifically, they are working to develop substitutes for PFAS currently in use – wherever this is technically possible and feasible with reasonable timeframes to develop and industrially scale up substitutes.

As industry representatives, we are also committed to ensuring that the idea of the “essential use” concept is taken into account. This provides for blanket exemptions for essential areas of life as well as high-tech applications, including medical devices. In addition, the use of PFAS-containing intermediates, process aids and plant components in industrial plants must remain possible.

In addition, due to the sheer quantity of indispensable PFAS for essential applications, broader exemptions should be defined on the basis of suitable substance groups (“PFAS of low concern”) that have already been scientifically proven to be harmless, i.e. non-toxic. An indefinite exemption for f luoropolymers and fluoroelastomers should be considered. ◆