Lens production going digital

Industry 4.0 creating business impact

Industry 4.0 offers new potentials impacting our business of producing ophthalmic lenses. Having realized automated mass production of individualized ophthalmic lenses with freeform technology developed by Zeiss and introduced in the year of 2000 is not the ending of improvements in lens production, but just the starting point of the fourth industrial revolution. Data generated by machines and where needed gathered as input by operators is the basis for Industry 4.0 with its target to create value out of data.

Industry 4.0 levels and use cases

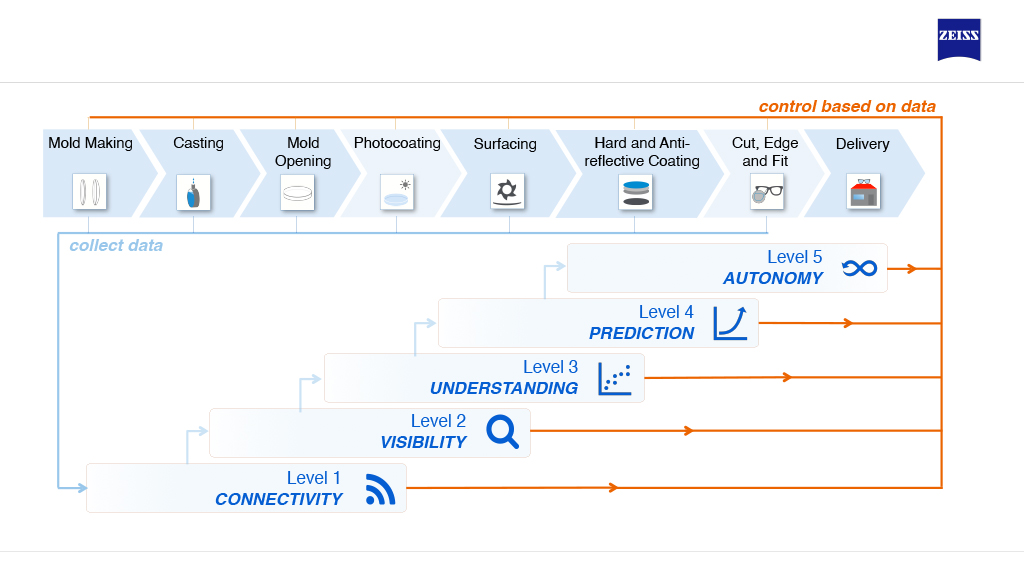

The implementation of Industry 4.0 cannot be mastered in one big step but needs to be developed from one level to the next (Fig. 1)[1]. First of all, data generated along the value chain of ophthalmic lens production needs to be collected and stored in data bases which requires “connectivity”.

The data then can be used to gain “visibility” about what is going on in the value chain and on the shopfloor by e.g. creating reports or implementing dashboards with Key Performance Indicators (KPIs), quality control charts and condition monitoring. Visibility allows to see more than what is visible on the shopfloor and to speak with data.

Based on it, “understanding” of dependencies and root causes can be gained by analyzing the data. For example, the data can be used by Six Sigma experts to solve problems in production by following the DMAIC process: Define, Measure, Analyze, Improve, Control.

In a further step, “prediction” of defects as well as machine errors and downtimes is possible.

Multiple regression or Artificial Intelligence can be used for predicting quality characteristics based on various influencing factors and thus for optimizing the parametrization of influencing factors in order to avoid defects. Also, predictive maintenance can be realized based on condition monitoring.

Reaching the highest level of Industry 4.0, “autonomy” means that reactions based on predictions are autonomously executed.

For example, depending on the use case, it can be decided to automize the optimization of the parametrization of influencing factors. This requires that risks and benefits are carefully evaluated. So, human beings might still be needed in executing reactions and definitely will play an essential role in developing analytical models with and without Artificial Intelligence.

Fortunately, it does not require to achieve the highest level of Industry 4.0 for creating business impact. Industry 4.0 use cases can be defined on each level. In order to select use cases for implementation it is helpful to prepare a business model for each use case and, as far as possible, to make a business case calculation.

The value created by each use case should be in line with the business need such as putting focus on quality, cost or service. Moreover, it has to be elaborated how value is created by each Industry 4.0 use case.

What Industry 4.0 use cases have in common is, independent of their Industry 4.0 level, that value is created out of data by controlling production based on data and thus closing the loop to production. In particular, the loop to production is closed either on a single process level, along several steps of the value chain or even along the complete value chain which might even be distributed among various locations globally.

So, the basis of all Industry 4.0 use cases is to collect data which is why “connectivity” is so important for realizing Industry 4.0 use cases and thus for creating business impact.

Connectivity as enabler for Industry 4.0

The requirements for “connectivity” go far beyond plug-and-produce. Definitely, quickly connecting machines to a Supervisory Control And Data Acquisition (SCADA) system or a Manufacturing Execution System (MES) and thus the internal production IT architecture in order to start production and saving respective costs for integration of machines into the production system is essential. However, for realizing Industry 4.0 use cases the data exchange between machines and SCADA or MES has to be enhanced.

Besides exchanging data that is critical to run production, for each use case it has to be identified which additional data is needed from which machine and which additional data needs to be shared with which machine for closing the control loop. Thus, it becomes clear that without enhanced data exchange Industry 4.0 use cases cannot be implemented. “Connectivity” is a crucial enabler for Industry 4.0.

So, what is needed to realize the 4th industrial revolution in ophthalmic lens production? Machine interfaces need to be standardized not only allowing for plug-and-produce, but also allowing for data exchange for Industry 4.0 use cases. This needs strong alignments between machine suppliers and ophthalmic lens manufacturers or even joint standardization activities between multiple suppliers and multiple manufacturers. Current standards like the Data Communication Standard (DCS) presented by The Vision Council could be updated in order to better comply with Industry 4.0 requirements.

The communication protocol needs to be defined in consideration of advantages and disadvantages of respective solutions such as TCP/IP and OPC UA. The data should be exchanged in a structured way such as by implementing information models including the name, data type and description of parameters.

The information models should be clearly defined, not leaving open any room for interpretation in order to avoid differences in the implementation done by various suppliers for the same machine type and thus enabling plug-and-produce.

Parameters which are independent of the machine type should be defined generally for all machine types and parameters which are specific for a machine type with its respective process should be defined machine-type-specific.

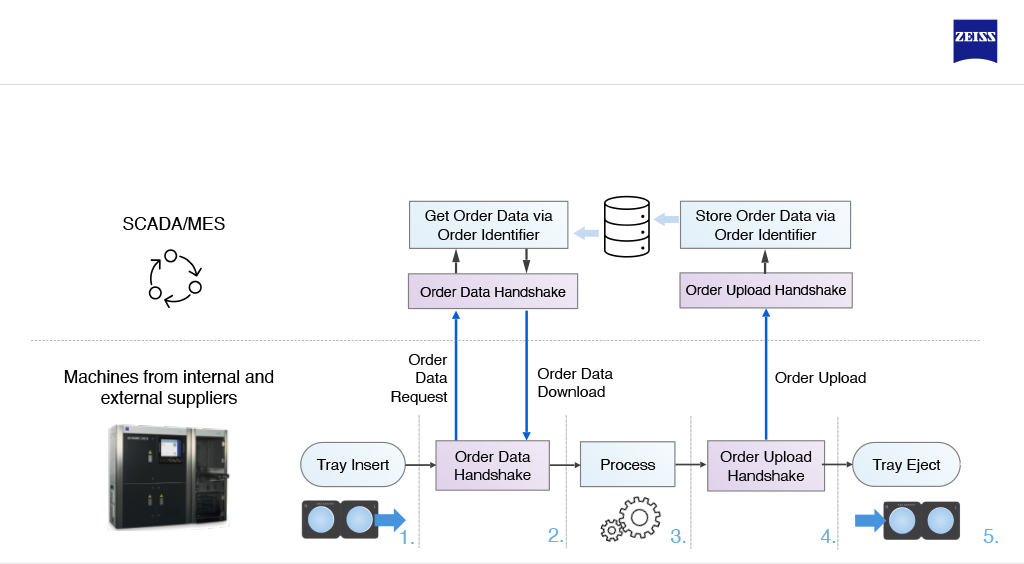

It has to be ensured that for each machine type general and specific parameters, that are needed for realizing to-be-implemented Industry 4.0 use cases, are considered. In this context, it has to be distinguished between order-related parameters that are directly related to an order that is processed in a machine and non-order-related parameters that are machine parameters that are continuously monitored in a machine and are not directly related to orders. Furthermore, handshakes have to be defined for exchange of order-related and non-order-related parameters.

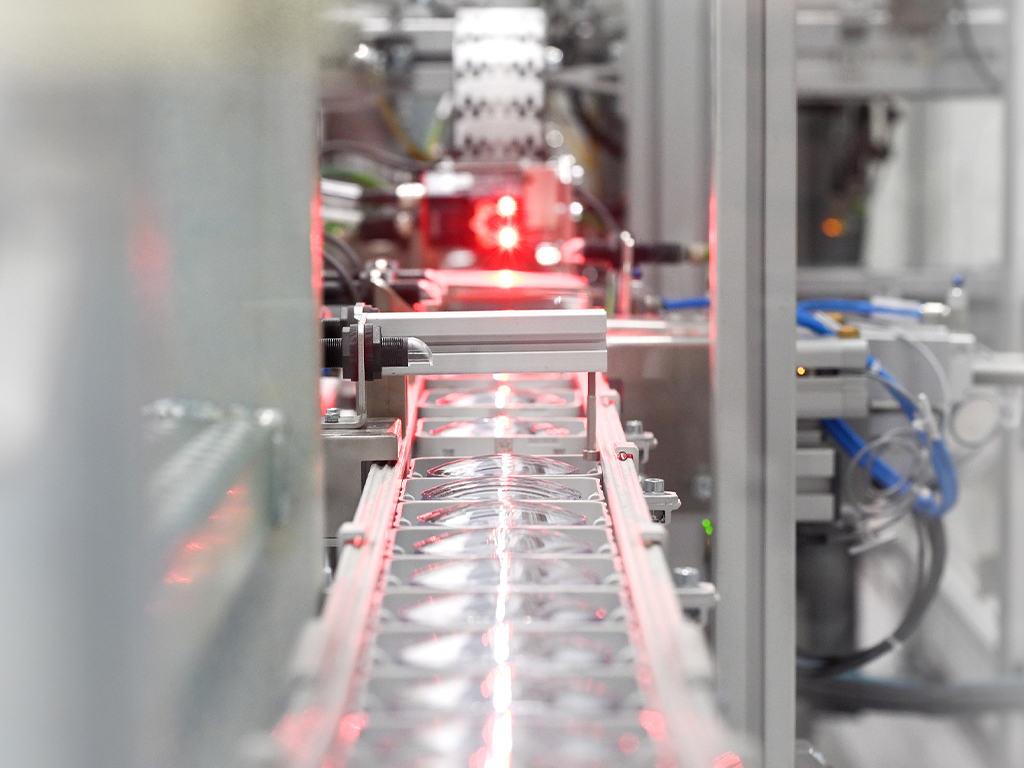

For order-related parameters handshakes are triggered by orders to be processed in a machine, e.g. by inserting a tray with to-be-processed lenses into a machine (Fig. 2). In a next step, data needed for processing a specific order is requested and transmitted or downloaded from a data base. After processing, order-related data about processing is uploaded or transmitted and then stored in a data base. Finally, the tray is ejected.

Dependent on the Industry 4.0 use cases, order-related data upload can include parameters that are useful for predicting quality characteristics and order-related data download can include parameters that are controlled by the prediction model in order to avoid defects.

Besides, order-related data upload can also include further information about processed orders such as the processing time of each order on a machine and conditions such as temperature during the processing of each order.

For non-order-related parameters, handshakes are not triggered by orders, but continuously generated data, such as temperature and pressure, can be continuously uploaded without any reference to orders, stored in a data base and visualized as time series.

In case the data required for an Industry 4.0 use case is not recorded, additional sensors might be installed. However, it should be avoided that required data is recorded by a machine, but not made accessible by the machine supplier for data upload.

The challenge of Industry 4.0, thus, already needs to be faced at the very first level which is “connectivity”. Machine suppliers need to be convinced by ophthalmic lens manufacturers to implement standardized machine interfaces for new machines and as upgrades for machines that are already running in production by now. Therefore, an industry-wide standard for “connectivity” could be beneficial.

Tools for data visualization and analysis

Based on “connectivity”, tools have to be selected and applied that are suitable for creating value out of the data according to the requirements of defined Industry 4.0 use cases. There will not be one tool which will be able to fulfill the requirements of all use cases and there might be several tools needed for implementing use cases on the different Industry 4.0 levels “visibility”, “understanding”, “prediction” and “autonomy”.

Depending on how value is created by each Industry 4.0 use case, a suitable tool has to be selected. Therefore, it might be helpful to conduct a utility analysis by comparing several tools based on defined use-case-specific criteria. As features usually differ between tools, testing of the tools could be useful to gain further insights and to come up with a profound tool selection.

Thus, data visualization and analysis should not be limited to a tool set provided by one single supplier on the market. In this context, it is important to understand that tools offered by machine suppliers have the huge shortcoming of limiting the implementation of use cases that go beyond single machines or even a set of machines offered by the same supplier.

Traceability in terms of unique identification of work pieces such as lenses allows for use cases that cover several process steps or even the complete value chain and thus might need “connectivity” of machines provided by several suppliers. However, not only tools provided by a single machine supplier, but also tools provided by a single software supplier may have its limitations in fulfilling the criteria of the internally defined use cases. In conclusion, an external dependency on a single supplier can be a big risk for realizing Industry 4.0 use cases.

It is important to create an Industry 4.0 tool landscape that is suitable for realizing the defined company-specific Industry 4.0 use cases – in our case for ophthalmic lens production. High effort is needed for structuring the use cases in a way that overlapping use-case-specific criteria as well as common user groups are identified. The target must be on the one hand to avoid having too many different tools overwhelming the users and on the other hand to provide the most important features that are needed for realizing the use cases and creating impact.

For some use cases there might be an interaction between tools needed. For example, one tool might be needed for a simulation of production systems with machines and material flows and another tool might be needed to visualize the simulation in Virtual Reality or Augmented Reality. Visualization in Augmented Reality would be especially helpful in cases where some production equipment is already set up on the shopfloor interacting with additional equipment that is under evaluation and can be augmented on the shopfloor.

Real-time data from the shopfloor can be directly accessed by the simulation enabled by “connectivity” in order to digitalize the physical production and then enhance the physical with the virtual production by using Augmented Reality.

Summary

Industry 4.0 offers great potentials to create value out of data and thus to impact our business of ophthalmic lens production. Therefore, Industry 4.0 use cases have to be defined along the Industry 4.0 levels. “Connectivity” on the lowest Industry 4.0 level is an enabler for realizing the Industry 4.0 use cases on all levels “connectivity”, “visibility”, “understanding”, “prediction” and “autonomy”. Thus, standardized machine interfaces for data exchange with machines are needed. For visualizing and analyzing the data according to the requirements of the Industry 4.0 use cases, an Industry 4.0 tool landscape has to be created.

References:

[1] FIR e.V. at RWTH Aachen: „Stufen des Industrie 4.0-Entwicklungspfads“

Jens Buergin

Dr. Jens Buergin is Head of Industry 4.0 at Zeiss Vision Care. He has been working in the field of Industry 4.0 for several years both in academia and in industry. Jens is convinced that Industry 4.0 offers great potentials for improving operations and even better fulfilling customers’ needs – and he is highly motivated to realize these potentials.