How digitalization and the Internet of Things will shape the lab of the future

The fusion of digitalization and the Internet of Things (IoT) is poised to usher in a new era for industrial producer across various industries, specifically within the ophthalmic industry with it´s one piece flow mass production. In order, to create the lab of the future through technology, it is imperative to understand these technological advancements and how labs need to adapt.

If we had computers that knew everything there was to know about things, using data they gathered without any help from us, we would be able to track and count everything and greatly reduce waste, loss, and cost. We would know when things needed replacing, repairing, or recalling and whether they were fresh, or past their best.” Kevin Ashton, who coined the term Internet of Things in 1999. (via Dataversity).

The Internet of Things

IoT describes an interconnected digital landscape, where devices are interlinked and share data with one another. While the term was first mentioned in 1999, and the actual use of the Internet of Things can be traced back to as early as 1980, IoT as we know it today can be tied to the rise of smart technology. Before smart technology, the internet was secluded to tablets, smartphones, computers and laptops.

However, digitalization has allowed for the rise of smart machines, which can be connected to one another in order to share data with the user, giving the user insight into how the device works. IoT promotes data-driven production, with real-time data being easily shared.

IoT and Industry 4.0

In the context of shaping the labs of the future, the Internet of Things plays a pivotal role in realizing the vision of Industry 4.0. Industry 4.0, often referred to as the fourth industrial revolution, represents a paradigm shift where digital technologies and automation are seamlessly integrated into industrial processes, giving rise to the concept of smart factories.

At its core, Industry 4.0 harnesses the power of Artificial Intelligence (AI), big data, and IoT to drive efficiency and enable manufacturing that is both flexible and highly responsive.

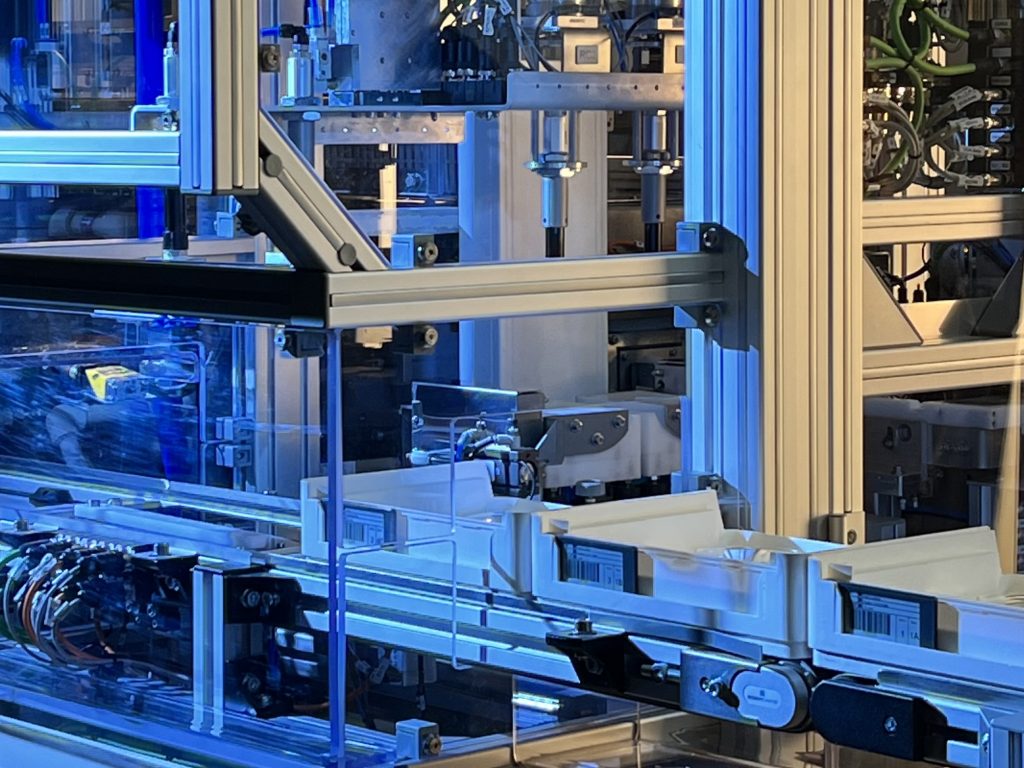

Within the industrial landscape, IoT sensors and devices serve as indispensable tools for collecting real-time data from machines and equipment.

This data forms the foundation for informed decision-making, predictive maintenance scheduling, process optimization, and the enhancement of overall operational efficiency. In essence, IoT not only provides the necessary data but also the connectivity essential for Industry 4.0’s ambition to revolutionize traditional manufacturing, fostering a more interconnected, automated, and efficient ecosystem.

Currently, AI adoption is on the rise, with a study by revealing that one in three IT professionals are already leveraging AI to automate various machine processes. The same study states that globally, 34% of enterprises have embraced AI, highlighting its growing significance in modern industries, the study also reports.

Data-driven production, empowered by IoT, is ready to play a pivotal role in shaping the future of manufacturing. It entails the generation and vertical sharing of real-time data, facilitating close collaboration between data scientists and production experts to enable AI applications. To propel laboratories into this data-driven future, there are four critical considerations.

IT system architecture needs to adapt

To fully leverage the opportunities presented by data-driven production, it is essential to begin by adapting the IT architecture. While many production lines are currently connected to the internet for tasks like uploading customer data, their connectivity is often constrained by the protocols in use.

So, how can IT systems evolve to address this challenge? One potential solution involves transitioning the IT system infrastructure towards a standardized architecture rooted in web technologies that can accommodate all devices, thus unlocking maximum productivity.

To make this transition successful, it is crucial to establish the right protocols. These should facilitate robust connections, enabling seamless data transmission and processing capabilities, both vertically from machines to the cloud and horizontally between machines.

This level of connectivity empowers operators to gain real-time insights into their production line. For example, they can access a snapshot of a distant machine’s status, diagnose errors, and make informed decisions – all at the click of a screen. Unfortunately, achieving this level of connectivity remains unattainable without adapting the infrastructure. The realization of the laboratory of the future hinges on the adaptability of IT systems architecture.

Digitalization drives sustainability

In recent years, the relentless march of innovation and technological advancement has rendered many technologies from over two decades ago obsolete. However, there is one notable exception to this trend – the printer. Some labs have made an effort to transition to paperless operations, these endeavors often faltered due to their lack of ergonomic design, inability to seamlessly integrate manual processes, and subpar user interaction.

Yet, with the advent of the Internet of Things (IoT), the dream of paperless labs has become not only more feasible but also significantly more efficient and user-friendly. Satisloh’s paperless technology leverages a combination of Eletronic Ink, WiFi, NFC (Near Field Communication) and RFID (Radio Frequency Identification) technology to seamlessly display critical information on screens, resulting in an e-ticket (Fig. 2).

This innovation based on simple technology can truly replace the paper like never before, especially in all manual process steps such as batching lenses, providing operators with clear guidance on which lens belongs where – something that was previously inconceivable without visual aids. The advantages of paperless technology extend beyond efficiency and feasibility; they also contribute to the conservation of precious natural resources. By reducing the need for toner and paper, paperless solutions play a pivotal role in safeguarding our environment.

This is just one example of the environmental benefit of employing digitalization and IoT. According to Forbes, IoT machines are able to perform more functions and thus yield less energy, making them more environmentally friendly. IoT devices also use less energy through optimization, and use low-power or alternate energy sources.

Artificial Intelligence will create benefits if used appropriately

Currently, there is a megatrend of using AI within technology, with many use cases existing already. This transformative wave has yielded numerous practical applications, such as the utilization of AI in the IT industry for tasks like anti-virus software development and deployment.

With today’s technological advancements, AI algorithms have attained a level of versatility that allows them to master a wide array of tasks. Within the ophthalmic industry, this translates into the capability to train machines with exceptional precision, empowering them to identify imperfections like scratches or optical aberrations with remarkable accuracy.

Furthermore, by implementing AI-driven predictive maintenance and anomaly detection systems, machines can reduce downtime and enhance operational efficiency. They can anticipate when maintenance is needed or when components are likely to fail, thus preventing unexpected production interruptions.

AI’s pattern recognition capabilities play a crucial role in improving product quality. It can analyze intricate patterns in machine conditions and manufacturing processes, correlating these with the final product’s quality.

For instance, AI can monitor the amount of current used by the spindle during the lens-cutting process, ensuring precision and consistency. Additionally, AI’s image recognition capabilities enable machines to perform quality control tasks autonomously, detecting defects or variations in the final product’s appearance.

In essence, AI has the potential to revolutionize lens manufacturing by not only streamlining operations but also by enhancing the overall quality and consistency of ophthalmic products.

Smart supply: intuitive software for last-mile management

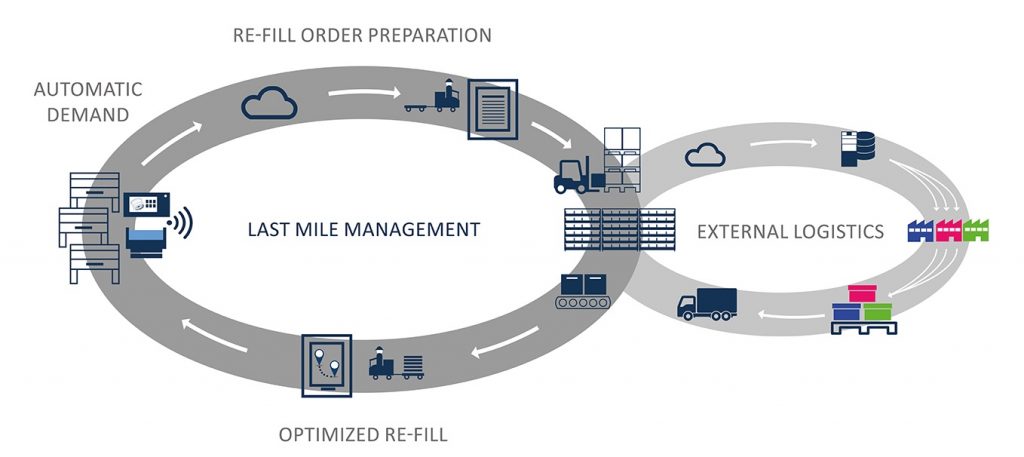

Today, many industries still adhere to a traditional, reactive approach when it comes to ordering and managing parts and consumables. This approach often involves labor-intensive, manual steps, such as identifying when new parts are needed, creating invoices, and coordinating with customers to understand their requirements. While this method still functions, its efficiency leaves much to be desired. Lab owners must find a productive approach.

However, there is a transformative solution at our fingertips: harnessing cloud-based computing and systems to automate the entire process can lead to remarkable improvements in efficiency and cost-effectiveness. Instead of relying on one-way orders and shipments, the future lies in machines directly generating demands for the parts and consumables they require. These are then delivered precisely where they are needed, right next to the machine. This approach eliminates manual steps and ensures that the necessary components are readily available. The introduction of tablets further streamlines the process, making supply management as simple as a single tap.

If, for instance, an additional machine is added to the production line to boost output, there is no need for intensive staff training or manual adjustments. Everything is handled automatically, leading to significant savings in both costs and operational efficiency.

Moreover, by leveraging cutting-edge IoT technology, we can further enhance this automated system by improving the recognition of when to order new parts. This not only amplifies efficiency gains but also ensures that the integration of new machines into the workflow is a seamless process, without the need for procurement of additional parts. The result is a more agile, cost-effective, and efficient production process that is primed for the future of manufacturing.

Embracing the lab of the future

The rapid evolution of digitalization and the Internet of Things (IoT) is poised to revolutionize labs, particularly those within the ophthalmic industry. This transformative journey is driven by a pursuit of greater efficiency, substantial cost savings, and a fundamental shift in how we approach quality control and production processes.

Efficiency is at the core of this transformation. The integration of IoT, digitalization, and automation streamlines operations, by reducing manual steps and optimizing resource allocation. As a result, the manufacturing of lenses becomes significantly more efficient, allowing labs to meet growing demands with greater ease.

Moreover, substantial cost savings are a key outcome of embracing these technologies. Predictive maintenance, automation of supply management, and precision in production all contribute to reduced operational costs. This allows labs to allocate resources more effectively, invest in further innovations, and remain competitive in the ophthalmic industry.

In the context of the ophthalmic industry, these advancements will have a profound impact on labs that rely on machines for lens production. They will be better equipped to meet the increasing demand for customized lenses, reduce production costs, and ensure that the quality of eyewear meets the highest standards. As labs adapt and embrace these technologies, they are poised to thrive in an era where the lab of the future is not just a vision but a tangible reality, offering better eyewear and improved user experiences.

Dr. Michael Kreis

Dr. Michael Kreis joined Satisloh and the optical industry in 2016. He is VP Global R&D for Satisloh, a leading manufacturer of surfacing, coating and finishing equipment. Kreis holds a Dr.-Ing. degree in Production Engineering from the Technical University Darmstadt, Germany. Besides his research activities on machine tool vibration behavior, his previous experience includes R&D management for high speed milling machines at Datron (Mühltal, Germany) and for steel beam processing installations at Kaltenbach in Lörrach, Germany.

Xavier Bultez

Xavier Bultez has been working in the optical industry for more than 15 years, currently he is Head of the Integrated Solutions Business Unit for Satisloh, a leading manufacturer of surfacing, coating and finishing equipment for the optical industry. Bultez’s previous experience includes Production Engineering at the Nikon Optical Rx labs in UK and Canada and Technology Manager at Essilor´s Engineering in France. He holds a mechanical degree from the ENSMM French Engineering School.