What If…

AI could optimize your lab and save resources daily?

Would you hesitate to trust decisions made by AI – especially if there were proof that it could reduce breakage, streamline processes, and significantly cut costs? Now is the time to realize; this is not a distant possibility. In fact, it is already happening: Artificial Intelligence is transforming industrial work – improving efficiency, detecting irregularities in delicate lenses, and making informed decisions on par with the highest skilled human operator. While many manufacturers already rely on automation to replace manual tasks, the true potential of AI in ophthalmic lens production is only beginning to unfold – particularly in quality control, from cosmetic inspection to power measurement.

There is a simple truth in production: to save money, you must control what you spend. Obvious, yes – but in complex environments like ophthalmic lens manufacturing, finding the savings is not straightforward.

In recent years, labs have increasingly turned to automation technology, seeking increased throughput and process efficiency that would ultimately reduce costs. And automation truly leads to optimized process efficiency and unprecedented machine utilization. Yet one crucial element has been missing until recently: “When we first had the vision for our Modulo Line system, more than a decade ago, we already knew that integrating quality control at an early stage – actually in-line – would be an essential element and prerequisite for a system to be truly automated and to unlock greater efficiency. Because automation without control is blind.” says Gunter Schneider, President at Schneider. “Especially because of the lengthy and delicate lens production processes, labs shouldn’t wait for the final inspection to learn about quality. They need an early warning system.”

By introducing automated, intelligent measurements earlier in the line, labs can detect quality drifts before they lead to breakage – conserving resources and preventing waste at scale. This level of early, reliable decision-making has become possible only with the rise of AI.

A look at the missed potentials in quality inspection

In many lens production facilities, general production issues such as miscalibration or tool wear are still detected too late in the process. This delay significantly increases the risk of higher breakage. The later a defect is discovered, the more costly it becomes to resolve. Another common challenge is the missed potential of measurement data in process analysis.

“For today’s operator, it’s often difficult to interpret measurement data and translate it into effective quality improvements,” explains Dr. Stephan Huttenhuis, Vice President Technology/Business Development at Schneider. “In many labs, statistical breakage analysis is still not implemented due to insufficient data availability. In my opinion, generating sufficient data and interpreting them into valuable actions is key for more cost-efficient production.”

To implement a holistic measuring system, Schneider has launched two solutions with individual approaches that add to their fully automated lab of the future. Smart devices will both check the quality of their product and point out the problems that cause any irregularities.

“Firstly, we have an on-block power measurement system that allows for in-line power measurement right after surfacing. Secondly, we have a system that combines full-map power measurement with AI-based cosmetic inspection. Implementing both features offers high potential to save time, costs, and ensure the highest product quality,” says Schneider.

Within the last years his team of AI-experts has trained new machines to recognize patterns, identify errors and help ophthalmic industries stay competitive and efficient in the face of rising price pressures. The strength of AI lies in solving problems for which a precise algorithmic solution would not be feasible, or prohibitively complex.

When a trained expert can quickly decide by looking at the data but will have a hard time explaining why and how they made that decision, you are likely looking at a prime use case for AI. This kind of task is very common in all aspects of industrial automation, from quality control to machine maintenance or process control.

Automated in-line quality inspection on the block

A new innovative approach enables ultra-fast measurement of the lens back surface while the lens remains blocked. This technique serves as an early warning system to ensure quality control from the earliest stage.

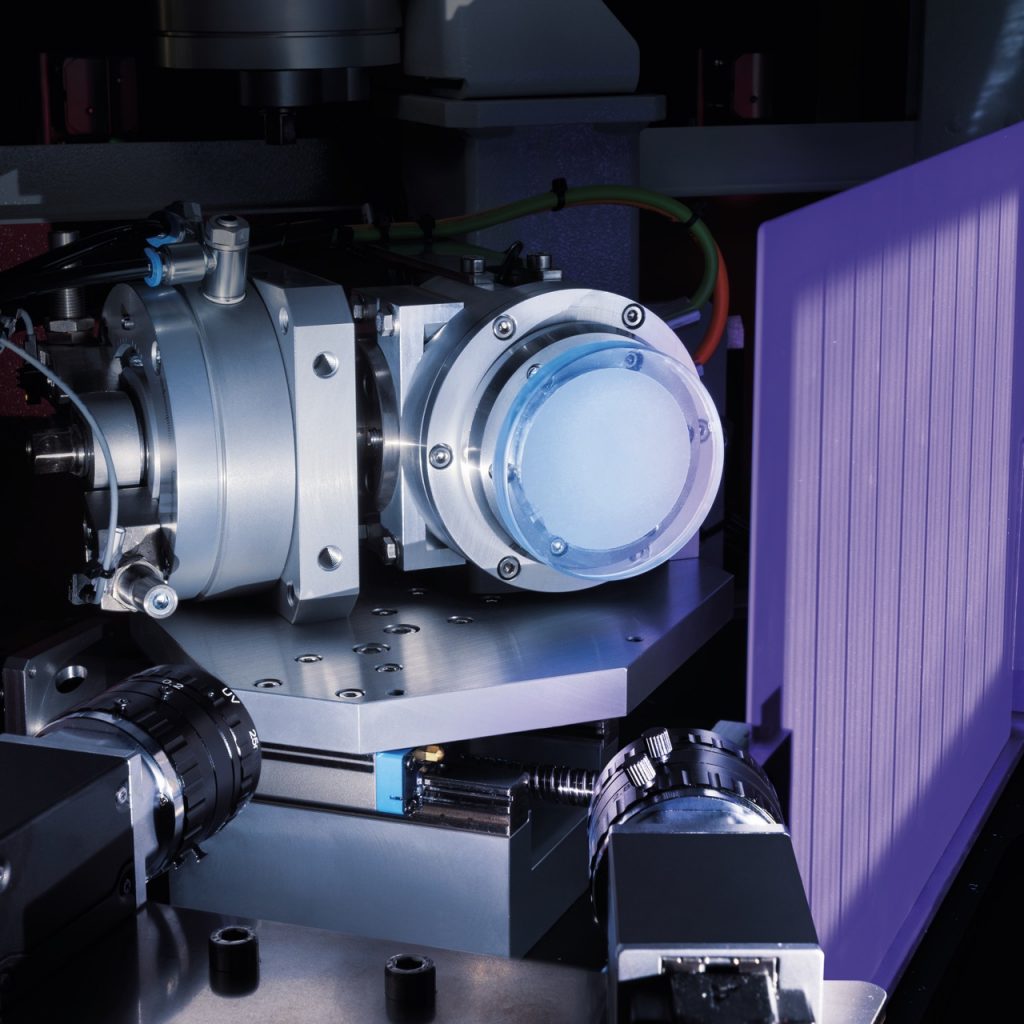

“With our full-map measurement system, PMD Modulo ONE, reflective measurement immediately after surfacing provides the earliest possible quality feedback,” explains Huttenhuis. The system automatically measures the lens diopter, assessing its optical performance. “Any deviations – such as those caused by worn tools or loose tape – are detected before costly downstream processes like cleaning, coating, or edging begin on a defective lens.”

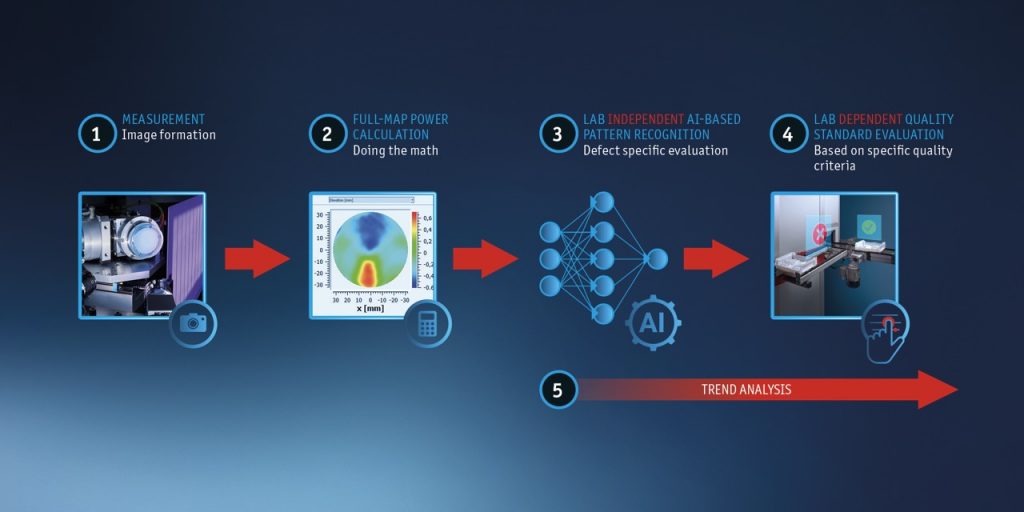

At the start of the measurement a camera takes images as a basis for full-map power calculation – doing the math. First comes a standard evaluation based on ISO, ANSI or other customer references – for near reference, distance reference and optical center.

This is followed by an extended pattern recognition in the second stage. The pattern recognition is AI-based and starts to identify specific defects, independent from the individual lab. Most quality inspection tasks boil down to computer vision issues: Which objects/irregularities are in this image, and where are they located. After this first detection, results will be evaluated by the AI, based on pre-defined criteria for lab-dependent quality standards.+

Over the last decade, AI has revolutionized the field of computer vision. Tasks that used to require complex and brittle hand-crafted solutions have become trivial and reliable, while many previously impossible tasks are now merely routine.

Overall, the early detection results in significant cost savings and shorter production times. Since it eliminates the need for deblocking, the on-block measurement method facilitates easy rework. Overall, it will help to reduce breakage and save resources. The early warning also ensures that all machines can be utilized most efficiently and are not busy processing defect lenses.

To get the maximum benefit from the early error recognition, real time data interpretation is required: The new system uses nominal surface data to generate and display an error map and ultimately guide informed decision-making.

The AI recognizes trends and picks up anomalies that may indicate a systematic problem very early on. “The supervised neural network is being used for the recognition of certain patterns, such as turning marks, center dots, waviness or block rings,” says Huttenhuis. “This way, it makes effective troubleshooting possible while still within tolerance – before breakage is produced.”

Fully-automated cosmetic inspection and full-map power measurement

While for the longest time automating cosmetic inspection was considered impossible, this has changed within the last years. The fully automated system CSI-P Modulo ONE relies on AI to analyze lenses and evaluate their surface quality.

It detects cosmetic defects, by screening the surface for irregularities, and characterizes and evaluates them. Just as in the on-block system, the AI conducts a lab independent pattern recognition to determine where potential defects are and how strong they are. The camera-based imaging system captures various configurations to analyze the lens.

Artificial neural networks sift through the data applying myriad algorithms and mathematical routines with hundreds of parameters. If irregularities or divergent regions are identified, pixels are combined and features are extracted.

Next, the intensity of each defect is rated and used as the basis for the decisions. The AI evaluates what kind of defect occurs and if it is relevant in this specific location and intensity. Based on the lab’s specific quality standards, the smart system decides if the job can pass or if it must be rejected.

Surprisingly, finding and identifying the defects proved to be much easier than deciding which defects in which locations are acceptable for a specific customer. This is mostly because human inspectors are very individual and usually do not have time to properly think about or document the reasons for their decisions. This made the collection of reliable training data a huge challenge that we needed to overcome in the first place.

Before the market launch, the cosmetic surface inspection had to distinguish and precisely determine a variety of types of irregularities – many of which look very similar to the trained eye or manifest differently depending on material and production method. This required the design and fine-tuning of novel architecture, as well as labeling thousands of individual images for training.

Now working with this database, the automated cosmetic inspection supports consistent and reliable evaluation and empowers AI to decide in the lab’s best interest. It considers customizable standards to reflect the quality standards of individual ophthalmic laboratories. Integrating transmissive power measurement into the cosmetic inspection system enables labs to assess all quality defining aspects in one shot at the end of the production process – to assure and comply with quality standards of outgoing goods.

This also convinces customers: “The decision to implement the CSI-P Modulo ONE was driven by our commitment to enhancing product quality and minimizing the influence of human subjectivity in both intermediate and final inspection stages. This advanced solution enables highly efficient and consistent control of cosmetic defects, optical power mapping, and center thickness measurement. Operating 24/7, the machine maintains a constant inspection speed and precision, ensuring uniform detection across all lens types” says Robert Szablowski, CEEMEA Regional Operations Manager, HOYA, Poland. “Moreover, the system supports proactive preventive maintenance strategies. For instance, the frequent appearance of rounded scratches may indicate wear in polishing components, allowing timely intervention before defects escalate. By reducing material waste, lowering complaint rates, and improving process stability, CSI-P Modulo ONE contributes significantly to our goal of achieving top market performance.”

Ultimately, this allows labs to implement the same quality routines across locations, e.g. various production facilities, to guarantee the same standards everywhere. But it also enables labs to apply differing standards depending on the demands of the product or brand produced.

AI-based process analysis and trend analysis

The key advantage of leveraging AI is its ability to combine data from cosmetic inspections and on-block power measurements for comprehensive trend analysis. By correlating this data with relevant metadata, AI can accurately identify and provide insights into the root causes of failures. All production data is seamlessly integrated into a centralized management system, giving operators immediate feedback on current performance. “Think of the Modulo Control Center as your production cockpit,” says Sebastian Schneider, Head of Edging and Coating Technology at Schneider. “It actively monitors performance, pinpoints issues, sends alerts, and highlights the proactive measures needed to avoid downtime.”

Rapidly, users gain access to all key insights – offering a level of transparency and operational understanding that significantly enhances decision-making. In addition, the smart system equips lab managers with a comprehensive set of tools to take control of their environment and implement changes effectively.

“At Schneider, we believe that beyond full automation, AI will fundamentally transform the ophthalmic industry. Vast amounts of data are meaningless unless properly classified and converted into actionable insights. AI enables us to unlock the full potential of this data, driving high-level process optimization,” summarizes Gunter Schneider. “And we are nowhere near the end of the line yet. Rather than simply increasing speed, ophthalmic labs will become smarter and more efficient than ever before”.

Dr. Marcel Mahner

Marcel Mahner holds a PhD in mechanical engineering from Technical University of Darmstadt, Germany. He started his industrial career at Schneider as Deputy manager mechanical design in 2018. Since 2022, he is managing the department of machine analytics and simulation at Schneider. In this role he is responsible for the development of measurement and simulation techniques.

Kim Kathrin Leidig

Kim Leidig holds a master’s degree in literature & media studies. With a decade of experiences in professional multimedia storytelling and content marketing strategies, she joined Schneider as marketing specialist to make the brand more visible. With her journalistic sense and passion, she tells their innovation stories from a new angle.