Sustainability in ophthalmic optics

An interview with Sylvi Claußnitzer

Complex, ambitious, and with some room for improvement. That is how one could describe the current state of sustainable measures in the optical industry. Sylvi Claußnitzer recently took over responsibility for regulatory affairs and sustainability at Spectaris. In the interview, you will learn more about why sustainability strategies are a success factor, what supply chains have to do with it, and which showcase projects already exist.

MAFO: What is your first impression of the optical industry in terms of sustainability?

Claußnitzer: My initial impression of the optical industry is highly complex. The German optical industry, for example, is undergoing structural change, characterized by consolidation, a shortage of skilled workers, and technological innovation. Despite these challenges, it remains economically robust and is growing strongly.

The industry represents a broad range of products, each with specific requirements in terms of manufacturing and supply chains. One example of this is ophthalmic lens manufacturing, which is particularly water-, energy-, and waste-intensive. Many companies are taking specific responsibility in this area: they have invested in waste-reduced manufacturing with closed cycles and water recycling, and they pay attention to energy-efficient production and the responsible and efficient use of chemicals.

The optical industry includes both global corporations and medium-sized, owner-managed companies. This diversity shapes the approach to sustainability: large companies work with internationally coordinated programs and clearly measurable targets for reducing energy, water, and waste. Smaller players, on the other hand, focus on flexible, practical solutions such as the use of renewable raw materials and regional supply chains. This creates an industry profile in which long-term strategic planning and immediate implementation ideas coexist or complement each other.

One area that could be improved, for example, is the holistic integration of sustainable processes into the entire value chain.

MAFO: Do you have examples of practical sustainability measures that have already been implemented in the industry?

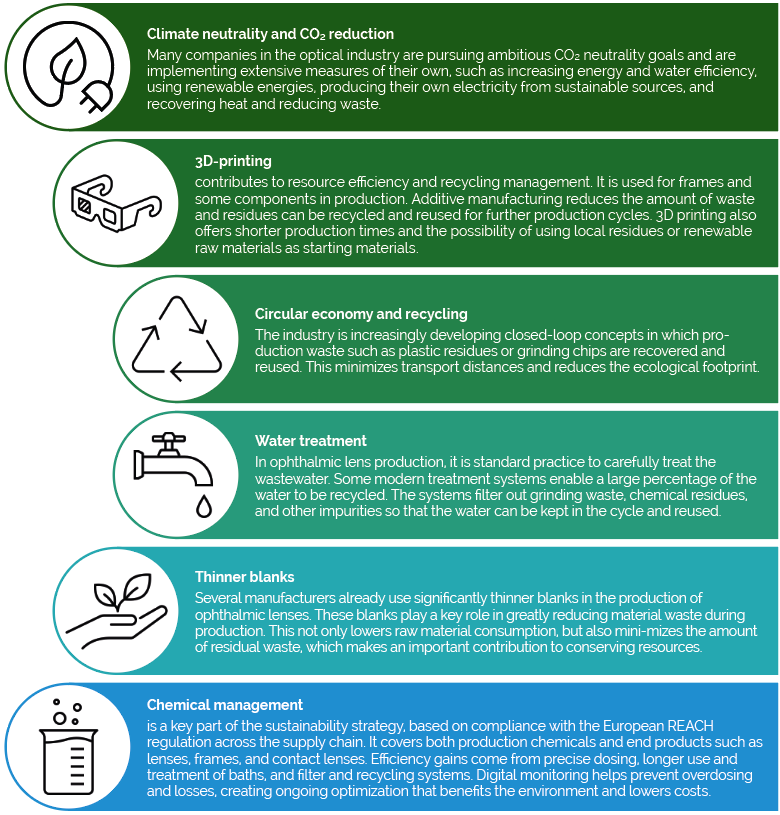

Claußnitzer: As an association, it is important for us to remain neutral and not highlight individual member companies. However, it is encouraging to see that some companies have already officially declared themselves climate-neutral. This is based only to a small extent on compensation mechanisms; the far greater proportion results from their own measures to improve resource efficiency. In other words, climate neutrality is not primarily based on “purchased” compensation measures, but on concrete changes in the companies’ own operations that have a lasting effect. There are also strategies for circular economy, water management, responsible use of chemicals, and much more (Fig. 1).

A good example of a new recycling concept is currently being established in Germany. It involves the PMMA-demo lenses in eyeglass frames. Opticians can now collect them in special collection containers. These are then picked up via a return system and taken to specialized recycling companies, which sort the material by type and recycle it. Thanks to cooperation between logistics service providers and recycling experts, the effort required by opticians is kept to a minimum and the ecological benefits are maximized.

But there are also other innovative approaches emerging. For example, minimizing microplastics in wastewater through novel filter systems, which filter grinding residues from the cooling water, dry them, and send them for further recycling. This significantly reduces the environmental impact of microplastics and enables water to be reused in the production process.

MAFO: What role do sustainable supply chains play?

Claußnitzer: Sustainable supply chains and transparency are increasingly in demand in the optical industry as legal requirements, growing consumer awareness of environmental issues, and the expectations of business partners are changing the market.

A key driver is the trickle-down effect: new European reporting requirements, such as those under the Corporate Sustainability Reporting Directive (CSRD), require large companies to report in detail on the environmental and social aspects of their supply chains. These requirements are automatically passed on to suppliers – and thus also affect many small and medium-sized companies in the optical industry that are not themselves directly subject to reporting requirements.

For the industry, this means that supply chains must be made more transparent, risks must be systematically assessed, and sustainability aspects consistently documented. At the same time, this offers opportunities: Companies that have their data under control and can credibly demonstrate sustainability can strengthen customer trust, secure their international competitiveness, and position themselves successfully in the market in the long term.

This makes it clear that sustainability in supply chains is not just a regulatory requirement, but is increasingly becoming a strategic success factor in the optical industry.

MAFO: The EU is also pursuing strategies such as the Green Claims Directive to stop greenwashing. What should companies know about this?

Claußnitzer: The EU’s planned Green Claims Directive (GCD) aims to prevent greenwashing by only allowing general statements such as “sustainable,” “environmentally friendly,” or “climate neutral” if they can be scientifically substantiated and transparently proven – for example, through life cycle analyses or certificates. The discussion surrounding the EU’s Green Claims Directive (GCD) clearly shows that the optical industry is also under increasing pressure to provide credible and verifiable sustainability information.

Exceptions are planned for small companies with fewer than ten employees and less than two million euros in turnover, but there is still concern in the optical industry that the administrative burden will primarily affect smaller businesses and that the competitive disadvantages will outweigh the benefits. Proponents, on the other hand, emphasize that uniform rules are necessary to create a level playing field and ensure credible sustainability communication. This could also help the optical industry in its transparent communication with customers.

MAFO: Are sustainability certificates a good tool for encouraging companies to act more sustainably?

Claußnitzer: Sustainability certificates in the eyewear industry can provide valuable guidance and credibility to the outside world. By complying with such certification processes, manufacturers can improve their environmental and social performance, meet legal requirements in a more targeted manner, and strengthen the trust of sustainability-conscious consumers.

Certificates such as EcoVadis or the Italian CSE seal promote structured review and continuous improvement of business practices throughout the entire product life cycle. They also support transparency along the value chain and offer an important differentiating feature in a growing market for sustainable eyewear products.

At the same time, critical aspects must be taken into account: Sustainability certificates are mostly voluntary and not universally binding, which leads to inconsistent adoption across the industry. Small and medium-sized companies in particular face high organizational and financial requirements that can make comprehensive certification difficult.

In addition, transparency about the actual environmental and social impacts is often limited, with the risk of superficial greenwashing. Many certificates also focus on specific aspects of individual processes and management systems, but not necessarily on actual sustainability performance across the value chain. This creates the risk that certificates remain formal proof and lose credibility if they are primarily used as a marketing tool.

Overall, sustainability certificates promote important standards and impetus in the eyewear industry and help to make sustainability visible and verifiable. Sustainability certificates are a useful tool, but they are not a panacea. It is crucial that certifications are realistic, tailored to industry-specific requirements, and accompanied by comprehensive implementation measures.

But I also like to emphasize that participation in such certifications is more than a question of public image. Certifications can help to anchor sustainability criteria in management through regular audits, review processes, and initiate improvements – especially in the optical industry with its complex materials and supply chains, this is a useful lever for achieving goals pragmatically.

MAFO: What is currently the biggest challenge in implementing sustainable solutions?

Claußnitzer: The industry is suffering from significant financial burdens due to inflation, high raw material and energy costs, and the consequences of global crises. These factors are consuming considerable resources that could otherwise be invested in sustainable innovations. At the same time, the shortage of skilled workers is causing personnel bottlenecks: there is a lack of qualified personnel to introduce new processes, adapt existing structures, or consistently implement technical solutions.

This is further exacerbated by a growing regulatory and administrative burden. New laws in the area of sustainability and supply chain management require detailed evidence, documentation, and reports. For smaller companies without specialized legal or sustainability departments, this often means an immense amount of work that ties up valuable time and resources. At the same time, many companies do not have the technical equipment or the necessary expertise to implement complex measures such as life cycle analyses, CO₂ balances, or modern recycling processes. Another obstacle is the current reluctance to spend.

In this situation, financial leeway remains limited, and even if companies want to act sustainably, they often lack the economic basis to do so. Support programs could help here, but many companies find the offerings too bureaucratic, difficult to access, or insufficiently tailored to the needs of the industry. Added to this is competitive pressure from larger companies, which can respond more quickly to sustainability requirements thanks to their larger structures and thus have advantages in the market.

The result: sustainability is often overshadowed by urgent survival issues in day-to-day business. Entrepreneurs are forced to focus on short-term stability, while long-term strategies fall by the wayside.

At the same time, those who keep their eyes open for sustainable opportunities despite all the hurdles can reap tangible benefits in the medium term. Even small, practical steps – such as switching to green electricity, investing in energy-efficient machinery, or optimizing water and chemical management – not only lead to ecological improvements but also result in cost savings.

In the long term, sustainable action opens up clear opportunities: those who make targeted use of innovations build trust with customers, strengthen their competitiveness, and increase their own resilience in times of crisis. The biggest challenge, therefore, lies not so much in a lack of will, but in the complex framework conditions – and this is precisely where policymakers, funding institutions, and associations are called upon to provide reliable structures and support.

MAFO: What sustainability goal would you personally like to see achieved in ten years?

Claußnitzer: In ten years, I would like to see an optical industry that remains competitive under clear and fair rules, invests its energy in genuine innovation and sustainable products, and thus demonstrates that economic success, social responsibility, and environmental protection are inextricably linked. The key to this is collaborative action – along the entire value chain and within the industry – with even more pioneers who courageously lead the way and more networked players who actively shape sustainability.

MAFO: Thank you very much for the interview.