Optimizing lens hard coatings

Spin, dip or both?

Optical labs around the world that perform hard coating applications are familiar with the options for hard coating lenses: spin coating or dip coating. Both have their advantages and drawbacks, and as a result, have varying levels of popularity and penetration in differing market segments. To dive deeper into the spin or dip inquiry, we must dig deeper into the advantages of each.

Spin coating is popular in the US, Latin America, and Indian subcontinent markets, while dip has been the process of choice in Europe and parts of Asia. The purpose herein is to provide a summary of the benefits of each to inform a prospective lab of the choices available.

Why is dip coating popular?

The general concept of dip coating is a very logical process: to apply a thin layer of liquid to a surface, particularly one as small as an optical lens, a simple dip into a large volume of the liquid is sufficient. The result is a thin layer of liquid that adheres and dries on the surface. Both the front and back sides of the lens are coated with the same material, producing identical indexes of refraction on both surfaces. This process is typically applied to large batches of lenses, coated all simultaneously, utilizing the same uniform procedure.

Lenses are submerged into a coating solution and slowly withdrawn to produce a uniform thickness. After coating, lenses are cured in a thermal oven for several hours, resulting in high-performance adhesion and abrasion resistance. This is a suitable method, assuming all steps and coating parameters are tightly managed.

Dip coating can be a sensitive process. Factors such as lens withdrawal speed and environmental conditions, like temperature, can make the dip coating process painstaking. Dip coating labs require a totally separate room for lens curing, whereas this can be avoided with spin coating, as the curing is integrated into the same environment as the coating itself.

Advantages of dip coating

- The same coating with the same index of refraction is applied on both sides of the lens.

- Generally better coating performance because these materials are solvent-based, thinner, and thermally cured for an extended period (measured in hours).

- Batch processing – a large group of lenses are processed at the same time and with the same index.

What is spin coating, and why is it on the rise?

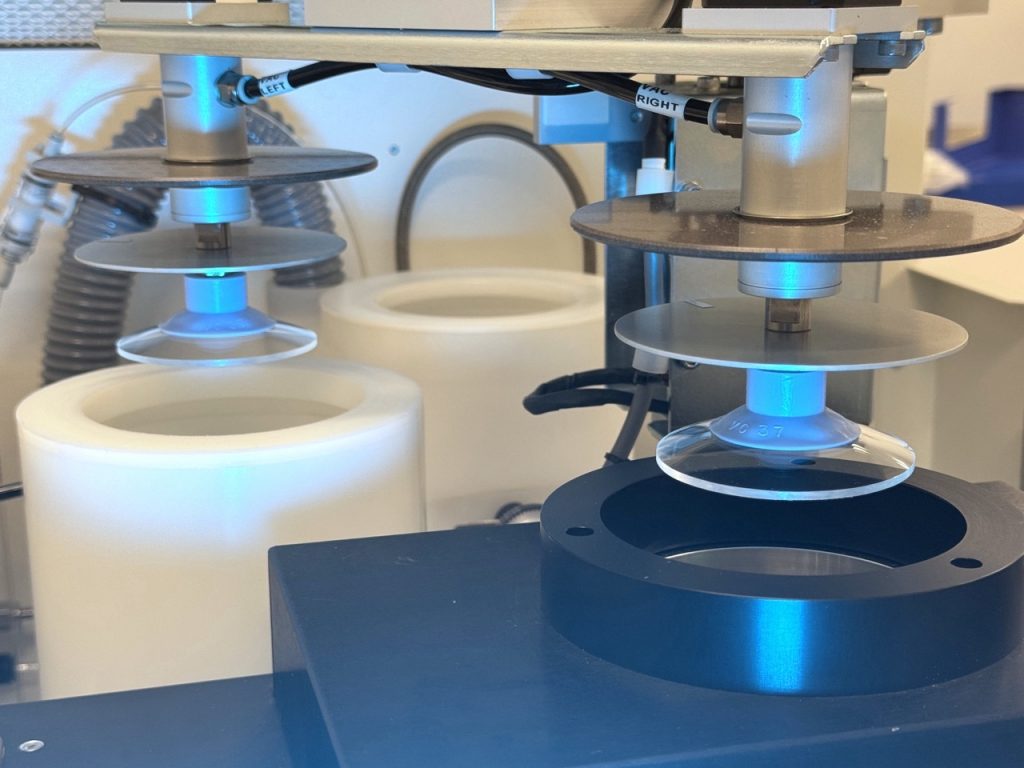

Spin coating is the process of applying a hard coating to a lens by way of a fountain of coating coming in contact with the lens while the lens is spinning. At high speeds, centrifugal forces evenly spread the stream of hard coating across the backside of the lens, also producing a uniform thickness. Curing is then performed with UV light on each individual lens rather than in a thermal oven.

Spin coating has obvious application and curing distinctions from dip coating: spinning the coating on the lens versus dipping the lens in coating, and UV curing the coating versus thermal curing the coating.

Advantages of spin coating

- Single piece workflow – fundamental to the lean manufacturing principles. The process can be stopped at any time, and should an error occur; an entire batch is not impacted, only a few lenses.

- Faster process is generally measured in minutes.

- Coating performance approaching that of dip coating. Technology has advanced significantly as it relates to new spin coatings, which are scoring higher Bayer, Tumble, and RLS scores than ever before.

- Smaller initial investment in capital equipment, as spin coating equipment tends to be more economical.

- Generally, utilizes solids-based coatings (without solvents) that are friendlier to the environment and operators.

- Automatable – the spin coating process is more easily automated, several companies offer machines that handle the entire process of cleaning, coating, and curing without manual operator involvement.

- Does not necessarily require a clean, dedicated room. Spin coating equipment provides its own “clean room” where the lens is coated and cured in one automated system.

An important application distinction

An important distinction between backside spin coating and dip coating is the application of coating to just the back side of the lens versus both sides.

Some lens blanks come from a manufacturer with a factory hard coating already applied to both sides of the lens. In these cases, the coating on the surfaced/backside of the lens, the side closest to the face in eyewear, is machined away when the blank is surfaced to produce the prescription. The factory hard coat remains on the front side, and it is only necessary to coat the back side. With spin application, coating just the back side of the lens saves time, materials, and cost because there is less surface area to coat.

Other labs will purchase uncoated (semi-finished) lenses and choose to dip-coat lenses to apply the same hard coating to the front and back side of the lens after the surfacing process. This can be beneficial because a consistent coating is applied to both sides of the same lens rather than a factory coating on one side and a separate hard coating on the other.

A closer look at workflow

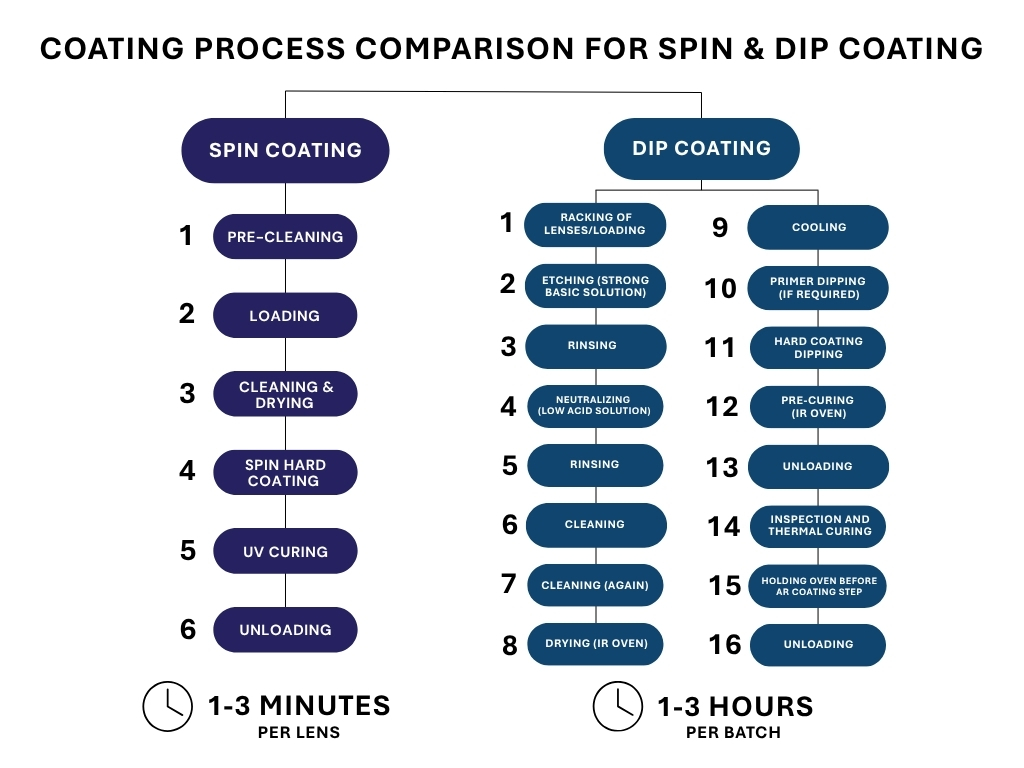

For labs of any size, deciding on systems best for the lab environment’s workflow is critical to an efficient and productive lab. Each single-unit system can be part of a larger, well-oiled machine that requires minimal disruptions. Ultimately, backside spin coating and dip coating have very different processes and steps (Fig. 3).

Spin coating employs a single-piece workflow, as one lens is processed at a time through each step, including cleaning, coating, and curing, and each of these process steps may vary depending on the specifics of each lens.

For example, a high-index lens may be cured differently than a mid-index lens. The spin coating equipment communicating with the lab’s LMS system knows the material of each lens and adjusts the process recipe automatically.

Lenses continually feed into and out of each process step of cleaning, coating, and spinning in steady state fashion at intervals of approximately 25 seconds. A benefit of this workflow is that lenses can be immediately handled after curing and unloading – but more importantly – the process can be stopped at any time should an error impacting lens quality occur. Then only a few lenses are impacted and not an entire batch.

The single-piece workflow is a fundamental concept of lean manufacturing concepts and is embodied ideally in the spin coating approach.

Dip coating requires more steps, but for mass production labs, the workflow may be worth the rigorous maintenance. It is also well established that thermal cured lenses have higher abrasion resistance and adhesion, though this advantage is lessening as spin coatings have improved significantly in recent years. Also, the dyeing options are more flexible with dip coating than with pre-coated blanks that receive their hard coating via spin coating.

A disadvantage of the dip coating workflow is that contamination could be costly and compromise yields. Contamination of a vat of coating can waste a batch of lenses at one time which can be disruptive to workflow.

The bottom line

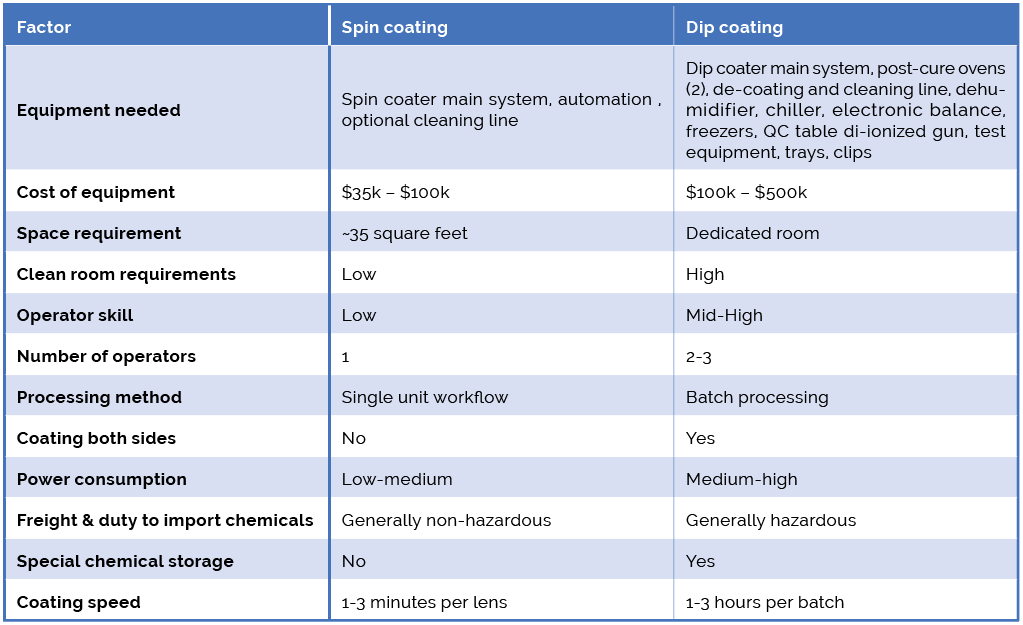

Each individual lab – whether it be corporate or independent, high or low volume – must weigh the advantages and drawbacks of each application method to determine which is appropriate. Factors to consider include space, cost, and skill requirements, choosing to coat just one or both sides of lenses, different dyeing processes or logistics including power, utilities, and chemical handling, quality, and yields.

Application method, workflow, maintenance, quality, and yields are among the top considerations when deciding which process to choose. A system that is optimal for one lab may not be optimal for another. Proper spin and dip coating systems are a significant investment, and research is crucial before integrating one into an optical lens processing lab.

And finally, for some labs, the question does not even have to be “either/or?” As, after all, integrating both processes can also be the best answer for some labs. Depending on individual lab requirements, dip and spin coating, with all their respective advantages and disadvantages, can actually complement each other perfectly.