Case study: Lens brush cleaning

Achieving superior cleaning efficiency

In order to consistently meet high-quality standards and develop innovative products, it is essential for operational managers to continuously review all process steps in the lens production for efficiency and sustainability criteria. At a well-known company in Germany, the operational team has identified optimization potential in the cleaning process for spectacle lenses. By adopting a state-of-the-art aqueous cleaner, the ophthalmic lens specialists have been able to make the cleaning step significantly more sustainable and efficient. A case study from Safechem and Hoya Lens Germany.

Achieving impeccable lens cleanliness is a cornerstone of the ophthalmic lens manufacturing process, as it directly impacts the quality of the final product. As a subsidiary of Hoya Vision Care, Hoya Lens Germany has built a reputation for quality and innovation in ophthalmic lens production. The DACH region (Germany, Austria, Switzerland) represents a key market for the company in Europe. Over 200 employees work in the production and administrative facilities in Moenchengladbach.

Challenges

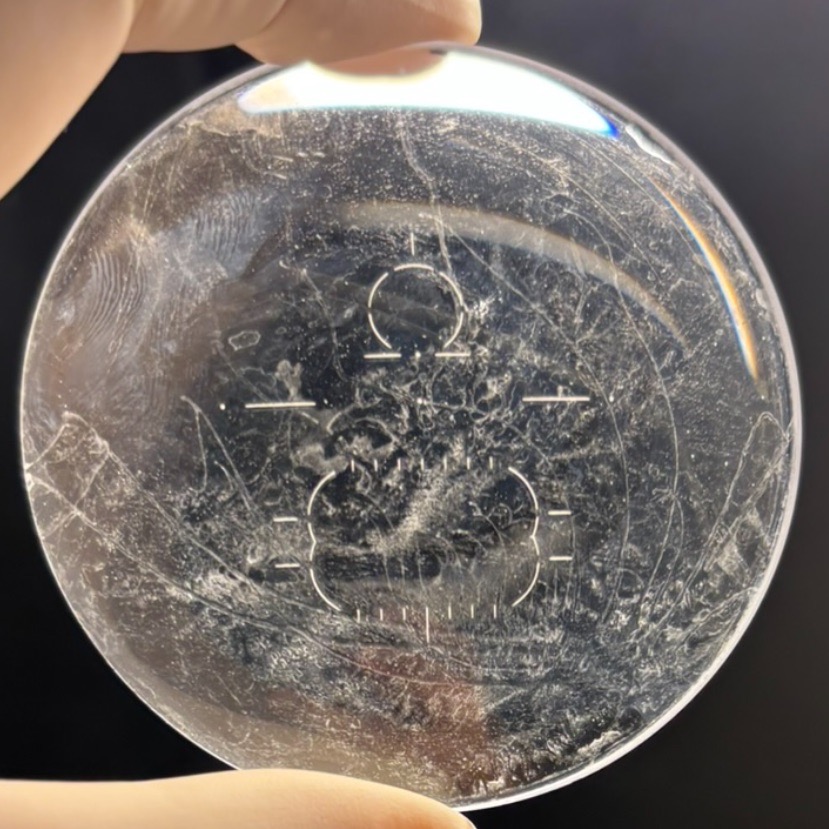

The previous cleaning process at Hoya Lens Germany, while effective, presented opportunities for enhancing operational efficiency and sustainability. One challenge was about the partial cleaning effectiveness. The existing cleaning solution occasionally left behind stubborn contaminants like adhesive residues, polishing compounds, and other manufacturing debris. This required additional manual cleaning, which increased labor requirements and extended quality control times.

Another area for improvement was the waste volume and further environmental considerations. The previous cleaning solution, with over 50% chemical content, contributed to a higher chemical residue in the wastewater. This necessitated frequent waste treatment and disposal, adding to operational costs.

And finally, efficiency was also a topic of discussion, especially in regard to the frequent brush replacements and elevated maintenance costs. The intensive cleaning chemicals contributed to excessive wear on the brushes in the brush cleaning unit. As a result, brushes required regular replacement because the hardened brushes could otherwise cause scratches on lenses, particularly high-index lenses that are more prone to damage. The frequent replacement cycle added to maintenance costs and interruptions to production schedules.

Solution

To address these challenges, the company adopted XZ O5-17, a state-of-the-art aqueous cleaner specifically developed by Safechem in collaboration with optics industry expert Dr. Quintus Khuen.

With a greatly reduced chemical concentration compared to the previous cleaning solution, the lab has achieved a cleaning process that is more effective, cost-efficient, and environmentally sustainable.

Improved cleaning results and reduced cleaner consumption

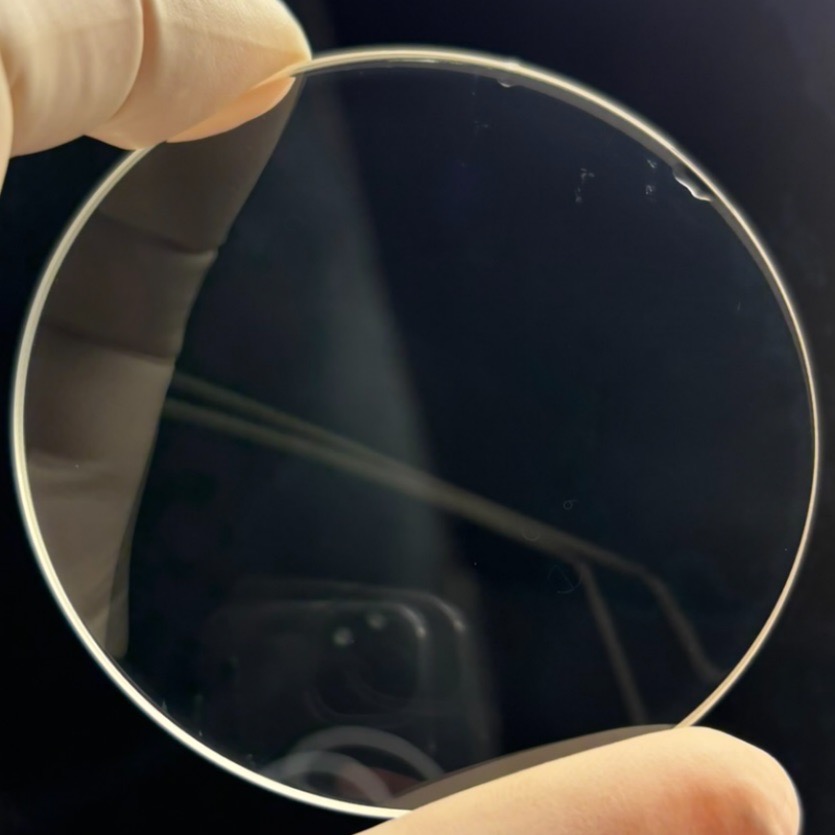

The switch to the new cleaner has transformed the cleaning process and led to exceptional cleaning results with reduced cleaner consumption. Contaminants like tough markings, adhesive residues, and polishing debris, which at times required manual intervention in the past, are now effectively removed during routine cleaning. In addition, cleaner consumption has been drastically reduced by 80%. To maintain its optimal concentration, operators replenish a small amount of cleaner at a regular interval (along with water to account for evaporation and carryover). Previously, much higher volumes of cleaner chemicals were needed for replenishment, and the cleaning tank required complete refills much more frequently. With the new cleaner the tank lasts ten times longer before requiring a full replacement, significantly reducing resource consumption and costs.

Increased maintenance efficiency

Furthermore, the change led to reduced maintenance frequency and costs. The optimized formula of XZ O5-17 is designed to be gentle on cleaning brushes, extending their lifespan by an impressive tenfold. Additionally, machine filters also last eight times longer, requiring far less frequent replacements compared to the previous cleaning process.

These enhancements have led to:

- Substantial reductions in maintenance costs.

- Fewer interruptions to production.

- Improved machine uptime and operational efficiency.

- Reduced waste volume and environmental impact

The lower chemical composition in the cleaning solution results in minimal carryover into rinse stages and the waste collection system. The wastewater now contains far fewer chemical residues and is much less hazardous compared to the previous solution. This shift has streamlined waste handling:

- The volume of waste requiring disposal has been reduced by a substantial 90%.

- Labor and resources dedicated to waste disposal have been drastically reduced.

- Operators face less exposure to chemical waste, creating a safer working environment.

The reduced waste volume and improved wastewater quality contribute to significant cost savings and a markedly lower environmental footprint, aligning with Hoya’s commitment to sustainability. “Everyone on the operational team is thrilled with the improved cleaning performance and the streamlined process. The results have exceeded our expectations, and we’re now recommending this solution to other manufacturing plants in Europe,” said Konstantin Kostov, Deputy Operations Manager at Hoya Lens Germany.