NEWS

Nearly 100 optical industry executives met for The Vision Council’s Lab Leadership Forum

The Vision Council successfully hosted the 2024 Lab Leadership Forum at the picturesque Temecula Creek Inn. This exclusive event saw a gathering of nearly 100 optical industry executives.

EssilorLuxottica closes the acquisition of the optical retailer Washin in Japan

Luxottica Japan, part of EssilorLuxottica, closed the acquisition of Washin Optical Co., Ltd., a Japanese optical retail player counting approximately 70 direct stores in the country with a strong heritage of quality and attention to consumers.

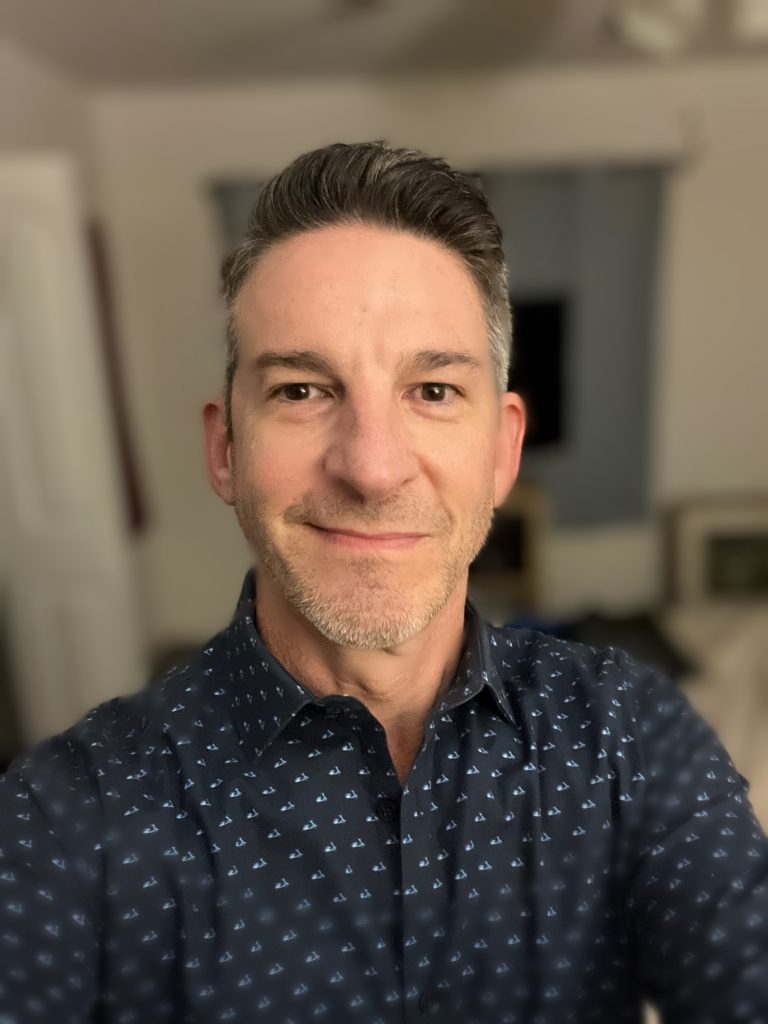

Coburn Technologies welcomes back Jason Frank as National Sales Manager – Coating Products

Coburn Technologies has welcomed Jason Frank back to their US sales team as National Sales Manager – Coating Products.

Xavier Maillard is the new Head of Region EMEA & India at Satisloh

Machine manufacturer Satisloh announced a leadership change in the region EMEA and India. Pascal Elsener, former Head of Region EMEA & India, is leaving the company and is succeeded by Xavier Maillard, the new responsible for the region.

Carl Zeiss Meditec completes acquisition of Dutch Ophthalmic Research Center (D.O.R.C.)

Carl Zeiss Meditec AG announced that, after securing all required regulatory approvals, it has completed the acquisition of 100% of D.O.R.C. (Dutch Ophthalmic Research Center) from the investment firm Eurazeo SE, Paris, France.

ISSUE 01/2024

Overview

Special topic: Smart Technologies: What labs need to be successful in the future // Adaptive smart glasses for future? // AR and MR devices as the next computing platform // Live on site: Great atmosphere at this year’s MAFO – The Conference // Mido 2024 ‒ back in force // Opti – a successful start to the new optical year // Market Surveys: Industrial edger // Business: Risk management – strategic and structured

FEATURED ARTICLES

Risk management – strategic and structured

In a rapidly changing world, risk management is playing an increasingly important role. The skillful handling of unforeseeable dangers has long since gone from being a nice-to-have to a have-to-have.

AR and MR devices as the next computing platform

Augmented Reality (AR), Mixed Reality (MR), and Extended Reality (XR) have been on everyone’s lips for some time. The first devices that came onto the market with AR or MR functions were mainly used in the industrial segment.

Adaptive smart glasses for future?

When your arm gets longer and longer after the age of 40 and the words in the newspaper seem to get smaller with every issue, it is time to take a look at the natural ageing process of the eye.

What labs need to be successful in the future

The economic trend in the ophthalmic industry is obvious: Due to demographic changes associated with rising demands and new markets, there is a continuing request for more.Simply put: a system that works for you.

Sales success 2024

Some people start the new year with a lot of confidence, while others are more worried. “Will I get enough orders next year?”, “Will I be able to push through my calculated prices?” or “What will I do if my best customer drops out?” are questions that make many people anxious. Others just hope that things will work out.

How can visually impaired people benefit from prismatic lenses?

According to the International Classification of Diseases 11 (ICD-11, 2019) vision impairment occurs when an eye condition affects the visual system and one or more of its vision functions. People with visual impairment often have partial or complete loss of visual perception, which manifests as a decline in visual acuity and/or visual field. That is why the term “low vision” is often used.

How digitalization and the Internet of Things will shape the lab of the future

The fusion of digitalization and the Internet of Things (IoT) is poised to usher in a new era for industrial producer across various industries, specifically within the ophthalmic industry with it´s one piece flow mass production. In order, to create the lab of the future through technology, it is imperative to understand these technological advancements and how labs need to adapt.

NEWS

Zeiss Vision Care acquires IP Portfolio for Electronic Eyewear from Mitusi Chemicals

Zeiss Vision Care announces the successful acquisition of a comprehensive intellectual property (IP) portfolio, including a suite of patents, from Mitsui Chemicals (MCI).

Mido successfully concluded with 40,000 attendees

The international eyewear trade show Mido hosted more than 1,200 exhibitors in the 7 pavilions of exhibit area and welcomed more than 40,000 attendees during the 3-day show, an 11% gain over last year.

ANFAO introduces CSE (Certified Sustainable Eyewear)

CSE, “Certified Sustainable Eyewear,” the first product sustainability certification program for the eyewear industry, was presented during Mido, the most international eyewear show.

Schneider announces new territory Sales Manager for Western US

Schneider Optical Machines has announced the addition of Darren Rosenthal in the role of Sales Director – Western US. In this role he will manage the sales of machinery and related technologies to customers in the Rx lens manufacturing space.

The Vision Council convened more than 300 Optical Industry Leaders in Naples, Florida

The Executive Summit in Naples, Florida, from January 22 to January 24, gathered 330 industry professionals on the white sands of the Gulf of Mexico for three action-packed days of networking, leadership development, and critical discussions that will shape the future of the optical industry

The countdown to Mido 2024 has begun

With just two weeks left before Mido opens, the leading international eyewear show has reached its 52nd edition. Opticians, buyers, journalists and trade professionals from around the world will meet at Fieramilano Rho from February 3rd to 5th for an advance preview of the latest in eyewear trends, business and innovations.

opti 2024 concluded: “a perfect kick-off into the optical year”

The opti organizers announced that this year’s opti ended very successfully and was a great success on all sides. This year’s opti inspired opticians as an industry highlight at the start of the year. 21,500 visitors appreciated the common hub of all protagonists from the ophthalmic world.

Vision Expo East: Conclusive and celebratory New York City show

Vision Expo East 2024, co-hosted by The Vision Council and RX, is on track to be a landmark event for the eyecare and eyewear industry worldwide, with over 450 eyewear and eyecare companies gearing up to display their latest products and technologies across an expansive 150,000 square feet of exhibit space for one final show in New York City before heading to the sunshine state.

Coburn Technologies celebrates 70th anniversary

Coburn Technologies celebrates the company’s 70th anniversary as a pioneering force in the optical industry. For seven decades, Coburn Technologies has been at the forefront of innovation, driving advancements in eyewear technology and shaping the way the world sees.

EssilorLuxottica showcases its smart and hearing aided eyewear innovation at CES 2024

For the first time, EssilorLuxottica will exhibit at CES in Las Vegas showcasing Nuance Audio, first-of-its-kind glasses with advanced hearing solution, as well as Ray-Ban Meta smart glasses and other innovative solutions in the world of optics.

MAFO – The Conference 2024 attracts many attendees

A top-class program and a large audience await participants at this year’s MAFO – The Conference in Milan. Ticket sales have already broken all records of recent years, meaning that the conference is once again attracting new attention after the break due to corona virus restrictions.